|

|

|

Project #7 - Taming your Hawk .60

|

Specifications

Bore: .907

Stroke: .937

Disp: .604

Weight: 15oz

RPM:

13,500 with pattern carb. and narrow blade 11-7 prop. 23,000 with large throat carb. and 9-7 racing type prop. |

Powerful

as well as attractive, the Hawk was Duke's first schnuerle ported

.60. Unusual features included a cylinder section made with integral steel fins and an ultra-hard piston made from low expansion aluminum. With an expansion rate comparable to that of iron, the piston could be fit much closer, however, it seems that, on some examples, this was pushed a bit too far. Although there was tremendous potential here, the Hawk also

exhibited a few problems that kept it from becoming as popular

as it could have been. The engine can be modified to overcome

these, however, the modifications are such that proper tools

and machining skills are required to accomplish them. For those

of you with the facilities, and skills, the following modifications

will allow your Hawk .60 to reveal it's true, and considerable,

potential.

|

The Problems:

There are two problems that must be taken care care of to smarten

up the Hawk. These are: excessive compression in general, and,

on some engines, an overly tight fit. |

|

Fixing the

Compression Problem:

The Hawk was the first of numerous Fox engines over the years

in which the compression was, in our opinion, just too high for

friendly operation when using typical sport fuels (10-15% nitro).

Although Duke claimed the engine would run well on fuel containing

up to 25% nitro, we never found this to be true. Even on lower

nitro fuels, these engines could be inconsistent, very finicky

to adjust, run hot, and flameout unexpectedly. We found that

lowering the compression was the only way to cure this. The addition

of shims alone was not adequate, and machine work to the head

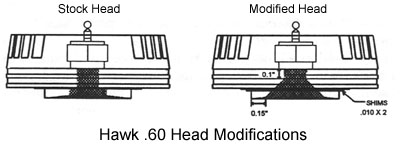

itself was also required. Material is removed in a cone-shaped

pattern as indicated by the shaded area in the diagram below.

Be warned that spare parts are no longer available if you

ruin the head. Proceed with care!

If you interested in having this modification done but cannot manage it yourself, we have a recommended

source for

custom machine work..

(Click on picture for larger view)

|

Important Note:

This modification will eliminate about half of

the glow plug threads. After the modification, use short reach

plugs!

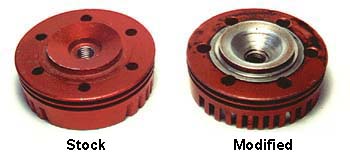

Here's a picture of a stock and

modified head

|

In addition to the head modification,

you will require two head shims made from .010" stock. If

your flying site is at a high elevation and/or you keep the nitro

content below 10%, you may get away without the shims. You can

experiment a bit here. |

|

Fixing the

Fit Problem:

The following quote from the Owners Manual will give you an idea

of what the problem is:

"In the interests of

good compression and long life we have fitted your Hawk as tight

as we dare. In the event yours is fit too close and you have

trouble with the piston seizing (engine stops abruptly on lean).....return

it to us and state your problem and we will hone it out at no

charge."

Since this engine has been out

of production for decades, it is unlikely that the offer from

Fox would still apply, free or otherwise. Of the two samples we have

in our personal collection one exhibited the seizing problem,

but we had the ability to hone it, which cured the problem.

If you also have this problem you will likely need to do the

same. |

|