|

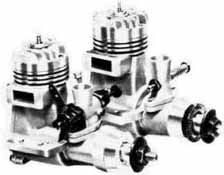

FOX 15 Schneurle OWNERS MANUAL |

|

NOTE The Fox 15 Schneurle has several unconventional features and operational characteristics that require handling different from the motors to which you are probably accustomed. It is imperative that you read this instruction manual completely before attempting to operate or disassemble the motor. SUITABLE MODELS The Fox 15 Schneurle is available with a variety of bearing, carburetor and head options. One of these combinations is suitable for just about any model use. BEARING OPTIONS The Fox 15 Schneurle is normally supplied with a high quality cast bronze main bearing; or at extra cost, two ball bearings on the main. The bronze main is a good quality material and generously proportioned and should give no problems during the life of the motor. The ball bearing version is recommended when the maximum ease of starting is desired or if you are planning to use the optional high compression head. CARBURETOR OPTIONS Your Fox 15 Schneurle is ordinarily supplied with either a standard control line type suction intake or a standard type RC carburetor. For special applications large throat carburetors and intake assemblies are available on special order. Call us for more information on these. HEAD OPTIONS The Fox 15 Schneurle bushing motor is normally supplied with a low compression head button in the interest of easy starting. The Fox 15 ball bearing motors are normally supplied with a medium compression head button which produces somewhat more power with reasonably easy starting characteristics. There are two high compression head buttons available, one for use with high nitro fuels for competition purposes, and the other for use with straight alcohol fuel as required for certain FAI competitions. We do NOT recommend these for sport flying. GLOW PLUGS TO USE The Fox 15 Schneurle is designed to use the Fox short standard or the Fox short idle bar plug. The short standard is lower cost and seems to be satisfactory for most applications. On RC motors if you experience an idling problem the idle bar plug will help. PROPELLER TO USE The majority of control line models and average sport type RC models seem to fly best with an 8" diameter 4" pitch propeller. For fast racer type models you may have better luck with a 7" diameter 5" or 6" pitch prop. We recommend the use of hardwood propellers of the maple & cherry variety. Softwood propellers such as gumwood tend to mash down at the hub and the propeller may come loose. We dislike plastic propellers because they hurt worse should you be so unfortunate as to get struck by a blade. |

|

WARNING Always keep clear of the propeller. It is possible for the propeller to cut a finger off, or for a piece to come out and put an eye out. |

|

FUEL TO USE We recommend Duke's Fuel or Missile mist fuel for ordinary use. In the event that you feel that you must use another brand of fuel be aware that many fuels on the market today use synthetic lubricants. We have destroyed hundreds of motors testing fuels and in every case the life of a lapped motor is drastically reduced where synthetic lubricants are used. Our tests indicate that a lapped piston motor lasts about ten times longer on our fuel than on the best of the synthetic oil fuels. BREAK IN The Fox 15 Schneurle is designed in such a manner that it is unlikely to freeze up. The non-sticking characteristics of a piston/liner fit make it possible for you to put a new Fox 15 directly into an airplane and fly it without bench running. We do recommend, however, that the first dozen flights be made with care to avoid over-heating. INSTALLATION Your Fox 15 Schneurle should be mounted in the most rigid and secure manner possible. If the airplane design calls for a firewall mount, we recommend our Fox one piece motor mount as it is very rigid. If your airplane is designed for beam type mounts we recommend you use hardwood beams and that they be very well braced at the firewall. A plywood firewall alone without cross bracing and gussets, just doesn't do the job right. A flimsy motor mount lets the engine vibrate and this in turn does all sorts of damage to the structure and may cause the fuel to foam, which in turn may damage the engine. |

|

WARNING There is always a possibility that you may lose control of your model. Do not fly in any location where your model might strike people or do property damage. |

|

NOTE If you have the urge to free up the cylinder/piston fit - DON'T. The Fox 15 Schneurle has been designed for equal cylinder and piston growth. The ideal piston clearance is zero. For those of you who may not believe us a new cylinder and piston can be obtained by calling 501-646-1656. MIXTURE ADJUSTMENTS It is desirable to fly your motor with your mixture adjustment set so that the engine has slightly more fuel than it actually requires. The extra fuel acts both as a cooling agent and supplies additional lubrication. With a control line type intake this amounts to merely adjusting the mixture adjustments for maximum power and then backing the adjusting needle out until the motor slows down slightly. In the case of the carburetor version it is somewhat more complicated. The Fox 15 carburetor has three adjustments on it. A low speed mixture, a high speed mixture and an idle speed adjustment. The low speed mixture adjustment is the one the fuel hose fits on. The high speed mixture adjustment is the one on the opposite side. The idle speed adjustment is reached from above. The recommended procedure for adjusting these is as follows: Start the motor and jockey the throttle arm until you get the engine running as slow as possible and still keep on running. Slowly work the slow speed needle in until the engine falters and then back it out until the motor slows slightly. If you have the adjustment right the engine will speed up slightly then die if you pinch off the fuel line. After the low speed mixture is adjusted then adjust the high speed mixture following the same procedure. |

|

WARNING Never fly a control line model within 200 feet of a power line. Death by electrocution is possible if your model comes near power lines, direct contact is not necessary. |

|

WARNING A model airplane engine can get hot enough to cause a serious burn. Do not touch the motor after running until it has had time to cool. |

|

DISASSEMBLY PROCEDURE If you wish to disassemble the Fox 15 Schneurle, first provide yourself with a clean place to work and a box to put the parts into so that you will not lose them. Then proceed as follows: 1. Remove the rear cover screws and the rear

cover. To disassemble the carburetor, first remove the low speed adjusting screw (pointing up) and the high speed stop screw (front). When these two are removed, then remove one of the needle clips and nut. The carburetor barrel can then be slid out. IN CASE REPAIRS ARE NEEDED The design of the Fox 15 Schnuerle is simple and you should be able to make most repairs yourself. If your dealer does not have the necessary parts in stock, they may be ordered direct from the factory either by phone or mail. Identify your motor as a Fox 15 Schneurle bushing or ball bearing motor, as the case may be. Then list both the name and number of the parts you need. In the even that you are not able to make satisfactory repairs, we will repair your motor but only with the understanding that no estimates can be given, no discounts can be given to dealers and we are authorized to make whatever repairs we fell necessary in order to put your motor back into first class operation. We do, however, give you our assurance that no repairs, exclusive of shipping costs, will exceed 60% of the price of a new motor. |